Each thermowell is an important component of any temperature measurement point. It is used to separate the process from the surrounding area, thus protecting the environment and operating personnel and keeps aggressive media, high pressures and flow rates from the temperature sensor itself and thereby enables the thermometer to be exchanged during operation.

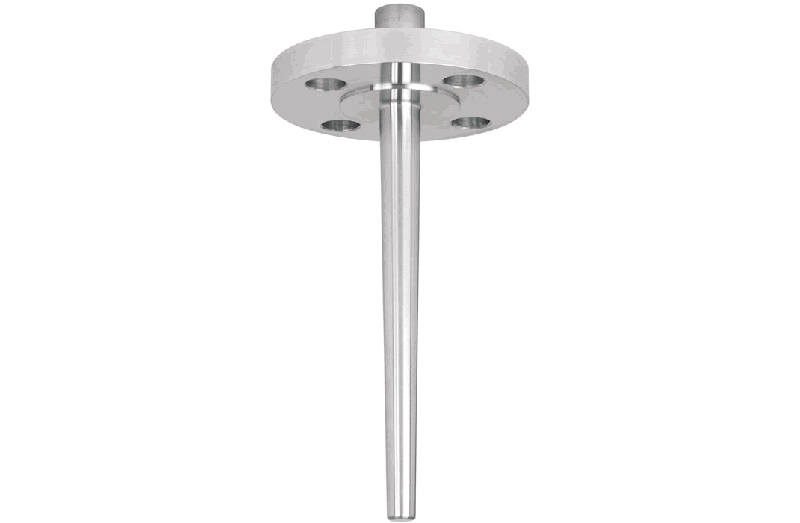

Based on the almost limitless application possibilities, there are a large number of variants, such as thermowell designs or materials. The type of process connection and the basic method of manufacture are important design differentiation criteria. A basic differentiation can be made between threaded and weld-in thermowells, and those with flange connections.

Special Features:

- Heavy-duty design

- Model TW10-F:

- Full penetration weld version

- Model TW10-P:

- With double fillet weld

- Weld seam strength a = 3 mm

- Model TW10-R:

- With double fillet weld

- Weld seam strength a = 6 mm

- Model TW10-F:

- Coating for corrosive or abrasive process loads

- Possible thermowell forms:

- tapered, straight or stepped

- “Quill Tip” version (with open tip)

- Welding process test to ASME Sec. IX

Applications

- Petrochemical industry, on-/offshore, plant construction

- For high process loads