These temperature transmitters are designed for universal use in industrial applications. They offer high accuracy, galvanic isolation and protection against electromagnetic influences (EMI).

In addition to the different sensor types, e.g. sensors in accordance with DIN EN 60751, JIS C1606, DIN 43760, DIN EN 60584 or DIN 43710, customer-specific sensor characteristics can also be defined through the input of pairs of values. The connection type is configurable, thus ensuring optimal connecting cable compensation. A cold junction compensation for thermocouples is built-in, while an external cold junction can also be used. The configurable error signalling (e.g. sensor break, hardware errors, sensor over/under-range) ensures a high degree of monitoring functionality.

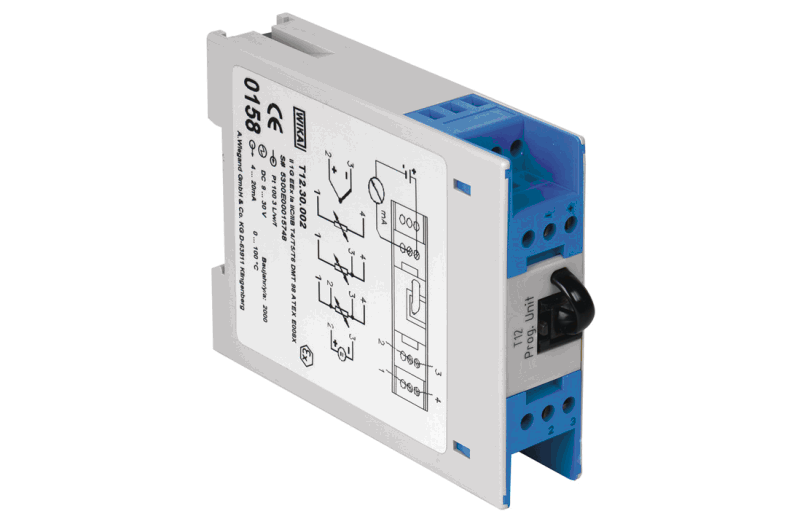

Configuration changes can be quickly and easily transmitted to the T12 using the WIKA_T12 configuration software (free download at www.wika.com) and the communication interface (programming unit), which is available as an accessory. The bidirectional communication makes it possible to display the measured values also on the PC/notebook.

The programming unit provides voltage to the temperature transmitter model T12, so that no additional voltage supply is required to configure the T12.

The dimensions of the head-mounted transmitter match the form B DIN connecting heads with extended mounting space, e.g. WIKA model BSS. The transmitters in rail mounting cases are suitable for all standard rails in accordance with IEC 60715.

The transmitters are delivered with a basic configuration or configured according to customer specifications.

Relevant Industries

- Aerospace & defence

- Alternative energy & CNG

- Dairy

- Diving & life support

- Energy & environment

- Food & beverage

- Industrial manufacturing & testing

- Laboratory and research & development

- Life sciences

- Microelectronics

- Oil & gas exploration and extraction

- Petrochemical refining and processing

- Personal care

Applications

- Process industry

- Machine building and plant construction